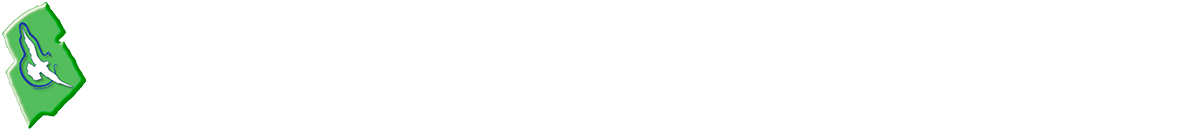

Heavy duty Lifting Magnet SYSTEMS FOR 5, 10, 20, 40 tonnes of steel PLATE, BEAMS, profiles, BLOCKS OR COILS: magnet systems for loading cutting tables.

Permanent-Electro heavy duty lifting magnets REQUIRE No battery back-UP SYSTEM.

Some of our Australian customers taking advantage of the safety and increased productivity offered by Tecnomagnete Permanent-Electro Heavy Lifting Magnet Systems from Serpent & Dove-Applied Magnetics. Some have multiple systems. Some have been in service for 20 years. Remember--no Battery Back-Up system with its extra weight and maintenance requirements.

Permanent-Electro (also known as electro-permanent magnets) use electric power only to energise and de-energise the magnetic lifting elements. There is no need for duty-cycling to limit temperature rise -- and no need for expensive and cumbersome battery back-up systems as required with conventional electro-magnetic lifters. Download product brochure here.

- Lifting magnet configurations for all shapes and sizes of steel

- Meets all relevant Australian Standards for magnetic lifting

- No battery back-up systems required

- Remote (wireless) operation

TM4/X, TM6/X, TM8/X - Permanent-electro magnets on powered telescopic beams

- Horizontal plate handling

- Operator selectable module combinations to allow handling of short or narrow plates

| Model | System weight (~kg) | thickness min. (mm) | width min. (mm) | width max. (mm) | length min. (mm) | length max. (mm) | WLL max. (kg) |

|---|---|---|---|---|---|---|---|

| TM4/100 X | 2500 | 5 | 500 | 3500 | 3000 | 12000 | 10000 |

| TM4/130 X | 2500 | 5 | 500 | 4000 | 3000 | 12000 | 13000 |

| TM4/160 X | 2500 | 5 | 500 | 4000 | 3000 | 12000 | 16000 |

| TM4/200 X | 2800 | 5 | 500 | 4000 | 3000 | 12000 | 20000 |

| TM6/150 X | 3800 | 5 | 500 | 4000 | 2800 | 16000 | 15000 |

| TM6/200 X | 4000 | 5 | 500 | 4000 | 2800 | 16000 | 20000 |

| TM6/250 X | 4000 | 5 | 500 | 4000 | 2800 | 16000 | 25000 |

| TM8/200 X | 4500 | 8 | 500 | 4000 | 2500 | 20000 | 20000 |

| TM8/260 X | 5000 | 8 | 500 | 4000 | 2500 | 20000 | 26000 |

TM4/X and TM6/X Also available as GTR4/X or GTR6/X magnetic cross-beams (BYO beam)

- Cross-beams only (with controller & accessories), to allow fitting to existing lifting beams.

- Magnetically equivalent to respective TM4/X or TM6/X model.

| Model | System weight (~kg) | thickness min. (mm) | width min. (mm) | width max. (mm) | length min. (mm) | length max. (mm) | WLL max. (kg) |

|---|---|---|---|---|---|---|---|

| BF2/50 X | 1100 | 5 | 500 | 3000 | 3000 | 6000 | 5000 |

| BF2/65 X | 1100 | 5 | 500 | 4000 | 3000 | 6000 | 6500 |

| BF2/80 X | 1100 | 5 | 500 | 4000 | 3000 | 6000 | 8000 |

| BF2/100 X | 1100 | 5 | 500 | 4000 | 3000 | 6000 | 10000 |

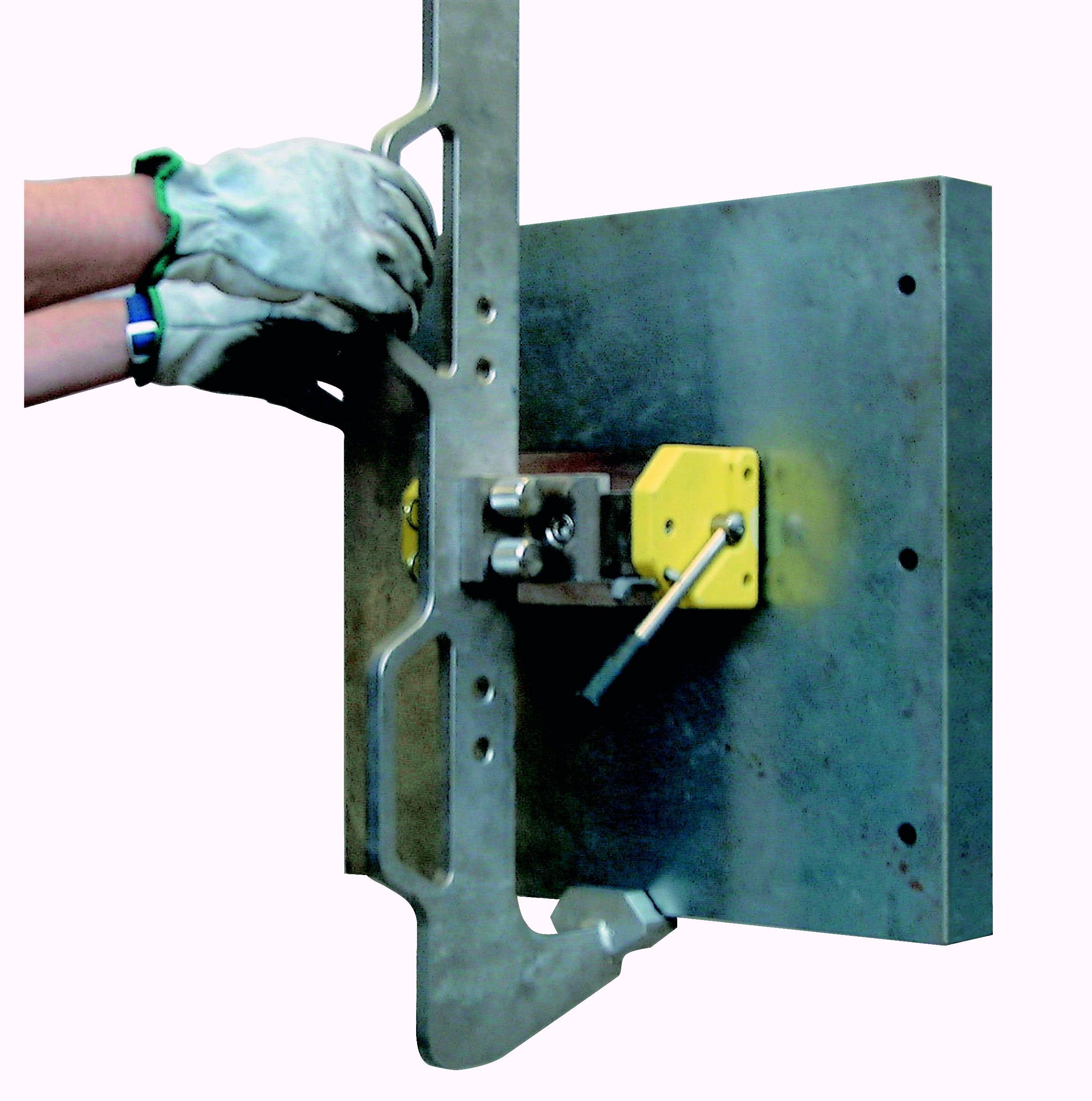

TB - Permanent-electro magnets on tilting beams

- Near-vertical plate handling

- Operator selectable module combinations to allow handling of short or narrow plates

| Model | System weight (~kg) | thickness min. (mm) | width min. (mm) | width max. (mm) | length min. (mm) | length max. (mm) | WLL max. (kg) |

|---|---|---|---|---|---|---|---|

| TB 4/35 | 1800 | 4 | 1200 | 3500 | 2000 | 6000 | 3500 |

| TB 6/35 | 2300 | 4 | 1200 | 3500 | 2000 | 12000 | 3500 |

| TB 2/60 | 2100 | 8 | 1200 | 3500 | 3300 | 6000 | 6000 |

| TB 4/90 | 3200 | 8 | 1200 | 3500 | 3000 | 12000 | 9000 |

| TB 4/120 | 3500 | 8 | 1200 | 3500 | 3000 | 12000 | 12000 |

| TB 6/180 | 6300 | 8 | 1200 | 3500 | 3300 | 18000 | 18000 |

TT - Permanent-electro magnets on fixed beams for cutting systems

- Load plate onto bed and clear cut plate plus skeleton in a single operation.

TTO for oxy and plasma cutting systems

| Model | System weight (~kg) | Cut piece min. size (mm x mm) | thickness min. (mm) | width max. (mm) | length min. (mm) | length max. (mm) | Plate surface max. (m2) | WLL max. (kg) |

|---|---|---|---|---|---|---|---|---|

| TTO/045 | 1300 | 250 x 250 | 4 | 1500 | 1000 | 3000 | 5 | 1100 |

| TTO/060 | 1800 | 250 x 250 | 4 | 1500 | 1000 | 3000 | 6 | 1500 |

| TTO/090 | 2700 | 250 x 250 | 4 | 2000 | 1500 | 6000 | 8 | 2200 |

| TTO/120 | 3800 | 250 x 250 | 4 | 2000 | 1500 | 6000 | 12 | 3000 |

| TTO/150 | 4000 | 250 x 250 | 4 | 2500 | 1500 | 6000 | 15 | 3600 |

| TTO/270 | 8000 | 250 x 250 | 4 | 3000 | 2000 | 9000 | 15 | 6500 |

TTL for laser cutting systems

| Model | System weight (~kg) | Cut piece min. size (mm x mm) | Thickness min. (mm) | Width max. (mm) | Length min. (mm) | Length max. (mm) | Plate surface max. (m2) | WLL (kg) |

|---|---|---|---|---|---|---|---|---|

| TTL/045 | 3000 | 70 x 70 | 1.5 | 1500 | 600 | 3000 | 5 | 1100 |

| TTL/090 | 5000 | 70 x 70 | 1.5 | 1500 | 1200 | 6000 | 6 | 2200 |

| TTL/120 | 6800 | 70 x 70 | 1.5 | 2000 | 2000 | 6000 | 8 | 3000 |

| TTL/160 | 9000 | 70 x 70 | 1.5 | 2000 | 2000 | 8000 | 12 | 3800 |

SML/X - Permanent-electro modules for single plates/semi-finished blocks (low air gap)

| Model | System weight (~kg) | thickness min. (mm) | width min. (mm) | width max. (mm) | length min. (mm) | length max. (mm) | WLL (kg) |

|---|---|---|---|---|---|---|---|

| SML 60 X | 350 | 5 | 800 | 3000 | 800 | 3500 | 6000 |

| 350 | 8 | 800 | 3000 | 800 | 5000 | ||

| 350 | 20 | 800 | 3000 | 800 | 6000 | ||

| SML 90 X | 450 | 5 | 1000 | 3000 | 1000 | 3500 | 9000 |

| 450 | 8 | 1000 | 3000 | 1000 | 5000 | ||

| 450 | 20 | 1000 | 3000 | 1000 | 6000 |

SMH - Permanent-electro modules for single slabs/forged blocks (high air gap)

| Model | System weight (~kg) | thickness min. (mm) | width min. (mm) | width max. (mm) | length min. (mm) | length max. (mm) | WLL (kg) |

|---|---|---|---|---|---|---|---|

| SMH 50 | 750 | 30 | 800 | 3500 | 800 | 6000 | 5000 |

| SMH 100 | 950 | 30 | 1000 | 3500 | 1000 | 6000 | 10000 |

| SMH 150 | 1350 | 40 | 1000 | 3500 | 1000 | 6000 | 15000 |

| SMH 200 | 1950 | 40 | 1000 | 3500 | 1000 | 6000 | 20000 |

| SMH 300 | 3100 | 60 | 1000 | 3500 | 1000 | 6000 | 30000 |

| SMH 400 | 4900 | 80 | 1500 | 3500 | 1500 | 6000 | 40000 |

Related News

Bat-Grip is suitable for lifting loads of up to 2 tonnes. Actual lifting is effected by permanent magnet elements. Phone on +61(2) 9971 7577 for supply to Sydney, Melbourne, Brisbane, Perth, Adelaide, Hobart and regional towns in NSW, Vic, Qld, WA, SA, T... Read More

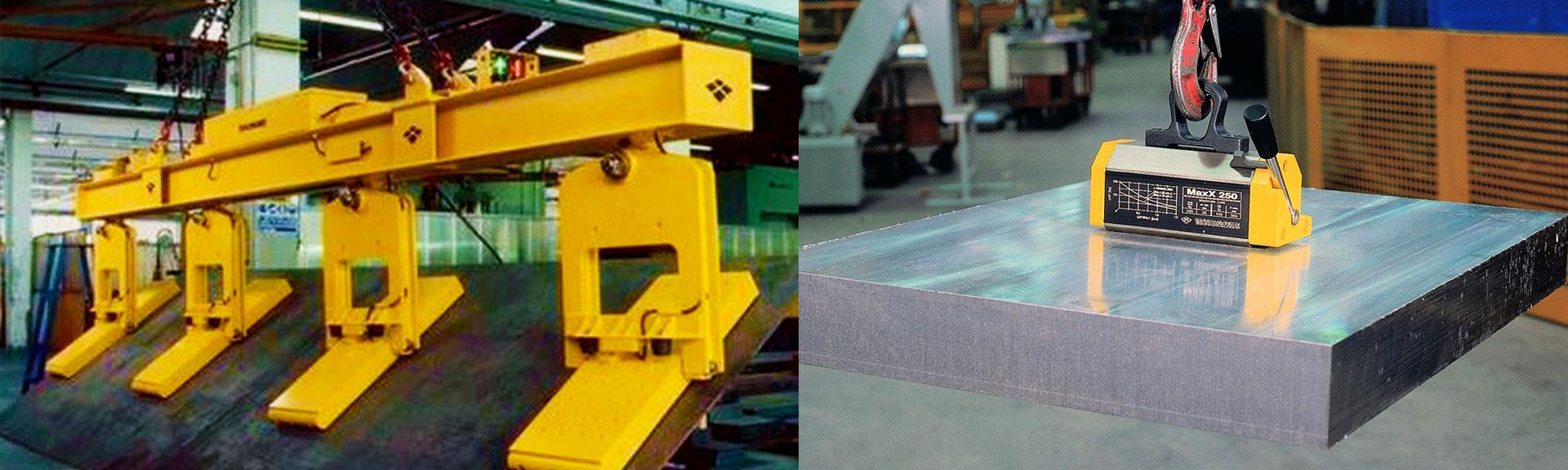

SERPENT DOVE Australia News: World's most used range of permanent magnet lifters come with a 5 year warranty. This exclusive warranty applies to all models of the Tecnomagnete MaxX series lifting magnets, from 125 kgs to 2000 kgs.... Read More

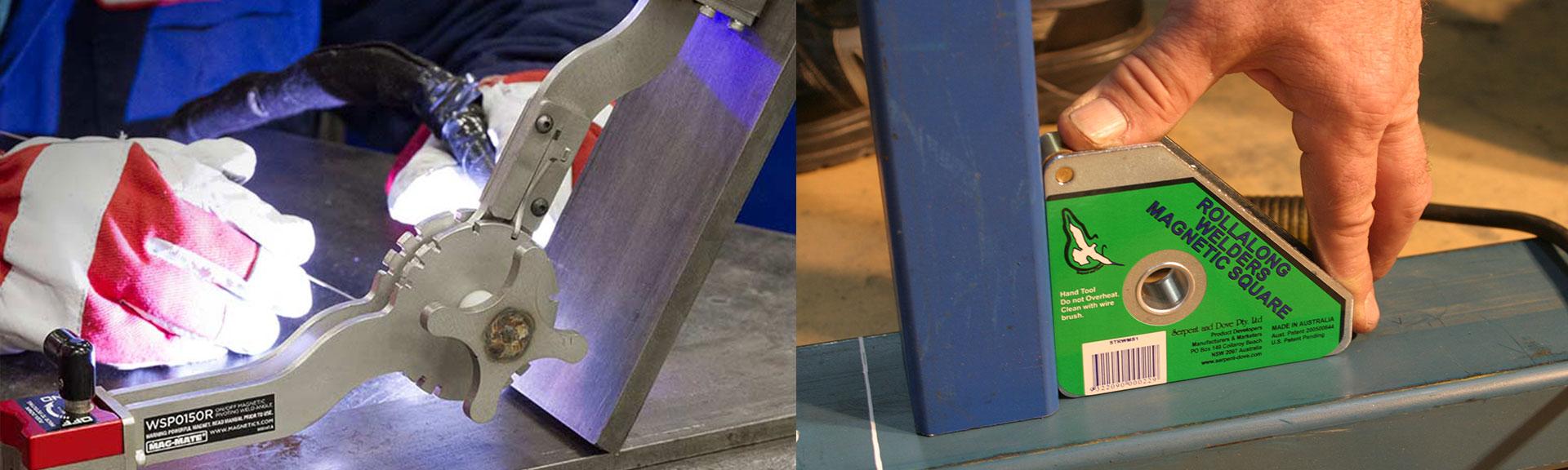

Rotating a load safely from horizontal to vertical with a Magnetic Lifter. Phone on +61(2) 9971 7577 for supply to Sydney, Melbourne, Brisbane, Perth, Adelaide, Hobart and regional towns in NSW, Vic, Qld, WA, SA, Tas, NT... Read More

Tecnomagnete (represented in Australia by Serpent & Dove) is at the forefront of advances in magnetic lifting technology. Phone on (612) 9971 7577 for supply to Sydney, Melbourne, Brisbane, Perth, Adelaide, Hobart and regional towns in NSW, Vic, Qld, WA, ... Read More

SERPENT DOVE Australia News: Tecnomagnete has perfected neutral crown technology that puts all the lifting power at the face of every lifting magnet they produce. This technology applies to permanent and permanent-electro lifting magnets alike.... Read More

Serpent-Dove Australia. The Easy Lift magnetic lifting system is lightweight and can be easily transferred from one crane to another as the power supply is onboard.... Read More