TECNOMAGNETE PERMANENT-ELECTRO MAGNETIC WORKHOLDING SYSTEMS FOR MACHINING

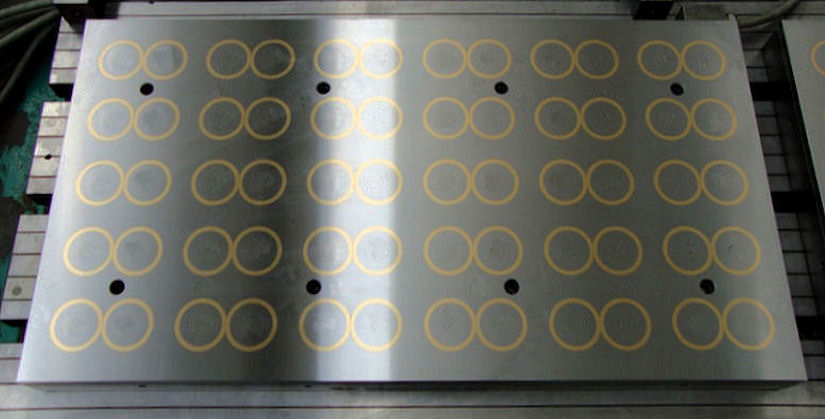

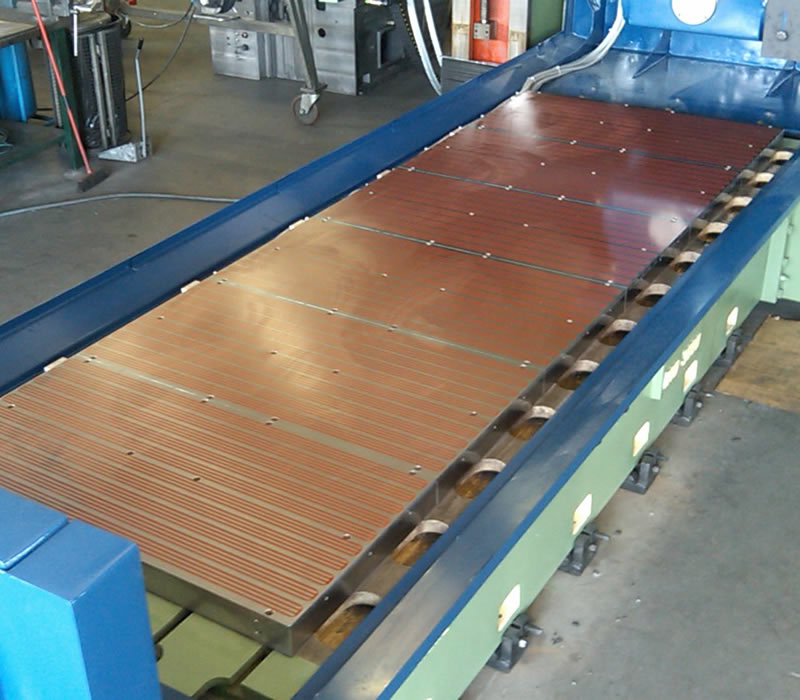

GRINDING CHUCKS

GrindTEC

-

For large parts (>200mm x 200mm)

-

Round Pole, full metallic surface

-

Minimum workpiece thickness 5 mm

-

Standard Size Range: 405mm x 600mm (model GT406HD) up to 570mm x 970mm (model GT610HD)

-

Also available as a round unit (GT/R), size range: D = 400mm (model GT/R0400) up to D = 1000mm (model GT/R1000)

TFP/TPF

-

For small parts (>50mm x 50mm)

-

Parallel Pole, steel/resin surface (TFP0); steel/brass surface (TFP1); steel/brass surface, fine pitch (TPF)

-

Minimum workpiece thickness 5 mm (TFP0, TFP1); 2 mm (TPF)

-

Standard Size Range (TFP): 300mm x 500mm (model TFP 305/T) up to 600mm x 1000mm (model TFP 610/T)

-

Standard Size Range (TPF): 150mm x 450mm (model TPP 1545/T) up to 400mm x 1000mm (model TPF 4010/T)

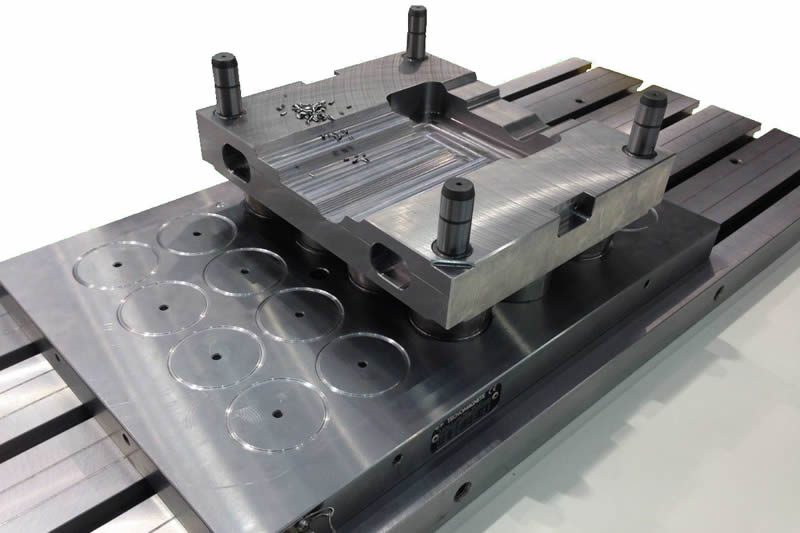

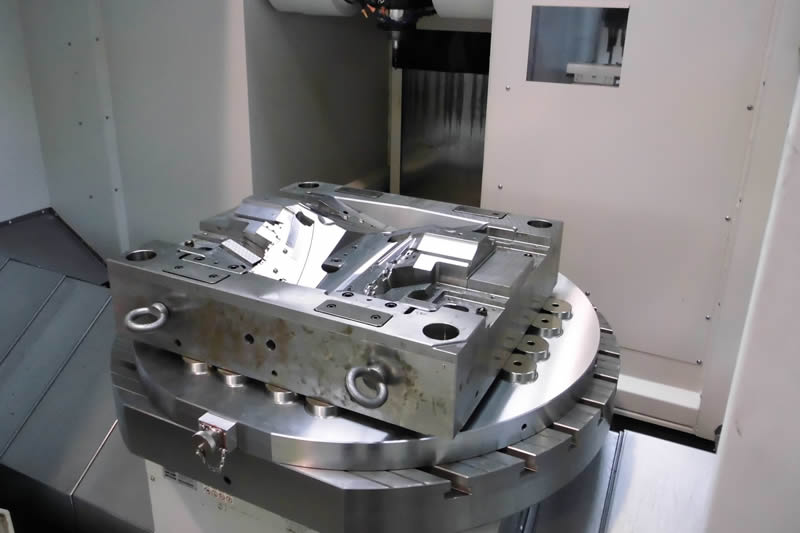

MILLING CHUCKS

MillTEC

MillTEC Basic

-

Mechanically fixed to the machine table.

-

Clamping force is distributed uniformly over the entire contact surface without any compression or deformation of the piece.

-

Standard Size Range: 320mm x 420mm (model MTB304) up to 570mm x 970mm (model MTB610)

MillTEC GRIP

-

Chuck Mechanically fixed to machine table but also magnetically attached across the whole lower face of the chuck.

-

Near-complete elimination of vibration of chuck or workpiece – higher tolerances, higher material removal rates, lower tool wear.

-

Standard Size Range: 320mm x 420mm (model MTG304) up to 570mm x 970mm (model MTG610)

-

Also available as a circular chuck (MTG/R), size range: D = 400mm (model MTG/R 400) up to D = 1020mm (model MTG/R 1000)

MTG/R